ICS SFC/SEE Modular Replacement Service for Your Siemens SGT5 F-Class Gas Turbines

Ageing static frequency converters and excitation systems are causing turbine starts to stop, violating grid codes, and exposing your plant to massive cyber and regulatory risks.

This makes your SFC/SEE your biggest single-point failure risk – and regulators know it.

Replace it now, before it costs you millions.

Why Your Siemens SGT5 F-Class Gas Turbine SFC/SEE is Now Your Biggest Single-Point Failure Risk

Aging (15-30 years+), obsolete or degraded Static Frequency Converters (SFC) and Static Excitation Equipment (SEE) on 1990s–2000s Siemens SGT5 F-Class gas turbine fleets are converging into a critical risk cluster and the leading cause of forced outages.

Left unaddressed, this doesn't just mean downtime – it triggers cascading operational, regulatory, and financial exposures.

Here's why the risk has never been higher.

Forced Outage = Lost Revenue

When your SFC or SEE fails, you can't start the turbine. No generation. No capacity payments. Direct loss of energy sales and potential grid penalties.

Grid Code Non-Compliance

Modern Transmission System Operator (TSO) requirements demand AVR/PSS models in PSSE format, on-load testing and validation which aging systems can't deliver . Risk of remedial action or unit derating.

Cyber & Regulatory Exposure

NERC CIP, NIS2, Cybersecurity Act and regional cyber rules are tightening. Legacy SFC/SEE systems with open remote access and unpatched Windows are non-compliant. Fines, audits, and personal liability for executives.

Spare Parts & Support Gone

OEM spare parts and factory support are no longer available. Repair lead times months-long. Each failure gets worse than the last one.

Poor Excitation Control

Degraded AVR response leads to voltage instability, reactive power swings, and increased stress on generator and network during faults.

Insurance & Financial Impact

Insurers and refinancers now demand proof of CII/BES cyber compliance. Non-compliant plants face higher premiums, reduced coverage, or loan conditions.

The question is not if your SFC/SEE will fail – but when!

And the cost of inaction far exceeds the cost of replacement!

Grid-Code & Cyber Compliance Baked In: From PSSE Models to IEC 62443

Modern regulators and TSOs demand more than hardware. Your SFC/SEE replacement must deliver documented, tested, and accepted models.

The ICS SFC/SEE Replacement service delivers compliance from day one.

Grid Code & TSO

AVR/PSS Delivery

IEEE 421.5 PSS2B models

PSSE format submission

On-load testing & tuning

EMA/ENTSO-E acceptance

Disturbance validation

NERC CIP

BES Cyber Compliance

Asset categorization (CIP-002)

Electronic Security Perimeter

MFA & centralized logging

Change & configuration audit trails

Incident response procedures

NIS2 & Regional

OT Security Hardening

Hardened OS baseline

Application whitelisting

Firewall & VPN architecture

Secure remote access with shared sessions

SBOM & vulnerability management

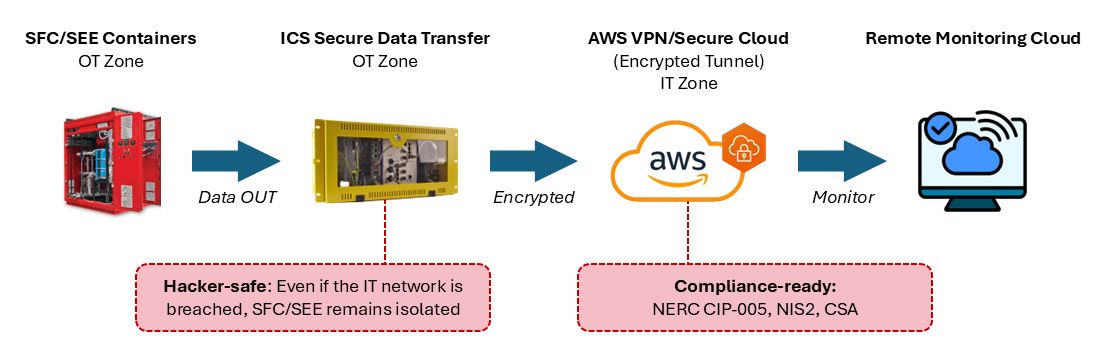

Integrated Data & Cyber Platform

Every SFC/SEE replacement comes with Bohemia Market's ICS Secure Data Transfer service – a hardware-based data diode and AWS cloud architecture that ensures:

One-way data flow – impossible for threats to traverse back through

Secure Data historian & trending for predictive maintenance

Multi-site monitoring from AWS with role-based access control

Real-time alerts and fault diagnostics with audit trails

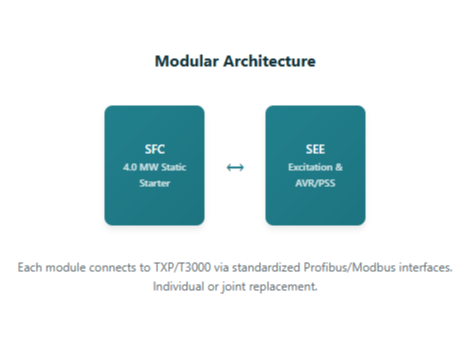

Modular Containerized SFC/SEE with Nidec – Replace One Module, Not Your Whole System

Unlike monolithic compact unit rebuilds, modular containerized static frequency converters and static excitation systems that lets you replace only what's needed, minimizing outage scope, and reducing installation risk.

Why Modular Wins

The traditional OEM compact-unit approach bundles SFC and SEE into one large unit, meaning when one of them fails, you have to replace both.

With a modular containerized design, SFC and SEE you can:

Replace SFC independently – the 4.0 MW static starter container holds thyristors and control for pure LCI-based starting, no excitation baggage.

Replace SEE independently – the static excitation container has its own redundant dual controllers, PSS, and limiters.

Reduce footprint – the containers fit existing UMC-level spaces with strict floor loading limits - no major civil work needed.

Reuse cables – engineering optimizes existing plant cabling to minimize new runs and firestopping.

Have shorter outages – each module is pre-tested and FAT'd; installation is plug-and-play via standardized interfaces.

Lower CAPEX & risk – replace only what's broken; defer second module if budget permits.

Be vendor agnostic – clean Profibus DP or Modbus TCP interfaces work seamlessly with T3000, PCS7, Ovation, or third-party DCS.

How ICS Secure Data Transfer Hardens Your SFC/SEE

Cybersecurity Hardening: ICS Secure Data Transfer + SFC/SEE

Your new SFC/SEE is secure-by-design, but connecting it to an aging DCS or corporate IT introduces risk vectors that regulators now scrutinize closely.

The ICS Secure Data Transfer service closes this gap – creating a cyber-hardened"data diode" between your SFC/SEE and your DCS/IT systems.

Secure Data Transfer Architecture

Key Features

One-Way Data Diode Architecture

Data exits SFC/SEE → encrypted through VPN to AWS

External systems cannot send commands back through diode

Impossible for external threats to manipulate SFC/SEE setpoints or parameters

Plant staff can view and monitor in real time; remote support engineers have shared-session transparency

Data Format Conversion & Historian

Native support: OPC UA, OPC DA, Modbus, IEC 104, MQTT, DCS protocols

Automatic conversion to standardized formats (OPC UA, SQL)

Built-in historian with AWS RDS backend for long-term trending

Central monitoring dashboard for 11+ power stations across 3+ continents (proven at reference customer)

Compliance & Audit Trail

All data transfers logged with timestamps (UTC, synchronized)

Role-based access control (RBAC) via Active Directory integration

AWS CloudTrail audit logs for all administrative actions

Incident reporting module: pre-configured for NERC CIP-008, NIS2 breach notification timelines

Remote Support & Cyber-Secure Maintenance

Plant staff and remote engineers see live system state simultaneously

No blind remote access; all actions shared in real-time

Meets YTLPS-style requirement: "Remote specialist can view and confirm every action they take"

VPN with MFA, certificate-based authentication, automatic session timeout

Case Study:

2 Complex SFC/SEE Upgrades Under Singapore's EMA and Cyber Rules

How Bohemia Market engineered a successful SFC/SEE replacement on a CCGT power station in one of the world's most demanding regulatory environments.

Pulau Seraya Power Station, Singapore, 2019 and 2022

Siemens SGT5 F-Class Gas Turbine SFC/SEE Upgrade

EMA-compliant, cybersecure upgrade of static starting device (SFC) and static excitation equipment (SEE) for critical Singapore grid stability

Replacement of aging GE SEMIPOL SFC/SEE on a Siemens SGT5-4000F turbine under EMA grid-code and Singapore cybersecurity regulations.

First retrofit was completed on unit 20 in 2019. Second retrofit was completed on unit 10 in 2022. Both retrofits were completed during regularly planned outages.

10-12 days

Outage window with multishift coordination

100% EMA

Grid code compliance validated on-site

IEEE 421.5

PSS2B model approved & tested)

IEC 62443

Cyber hardening & NESA audit completed

Challenge: The Perfect Storm

- Aging SFC/SEE with obsolete spare parts; repeated failures during starts

- Must submit AVR/PSS models to EMA in PSSE format, per Singapore Grid Code & SOM requirements

- Mandatory on-load testing and model parameter validating to EMA's satisfaction

- Cyber security audit: Legacy system non-compliant with UAE NESA standard and Singapore Cybersecurity Act

- Very tight 12-day outage window; Multi-shift work required; high coordination with crane provider (Siemens) and grid operator

- OEM claimed that that it would be impossible to integrate new SFC/SEE with existing DCS/TXP T2000

✓ What Was Delivered

Bohemia Market proved OEM wrong: New SFC/SEE seamlessly integrated with existing DCS/TXP T2000 – twice

GE SEMIPOL-Based Solution: Compact-unit SFC with dual-channel SEE controllers, thyristor-based SEE with advanced limiters and PSS, dual redundancy throughout.

This project did not use Nidec containers – it was a GE-powered retrofit – but the Nidec modular approach builds on these lessons to offer even greater flexibility and lower outage risk.

Singapore Cyber-Security Level 4 solution for GE Remote Access Visor Box: Making the GE device compliant through clever engineering.

✓ Regulatory Acceptance

EMA SOM Compliance: AVR PSS models submitted in PSSE format and validated via on-load testing with EMA participation.

Reactive power control, fault injection, and oscillation damping all certified.

Cyber Security: Full hardening per Singapore Cybersecurity Act – application whitelisting, firewall, VPN router for remote login, and shared-session remote support so plant staff see every remote action in real-time.

✓ Operational Impact

Start Reliability: New SFC enables unlimited start capability with optimized acceleration ramps and multiple modes (turbine start, black start, compressor washing, turning, boiler purging).

Voltage Control: Modern SEE with integrated PSS delivers industry-leading AVR response and damping, supporting Singapore's power grid.

Maintenance Shift: From frequent outages due to obsolete spare-parts unavailability to predictable, remotely diagnosed upkeep with structured spare-parts availability.

ZERO Cyber incidents since deployment!

Outcome: Regulatory Acceptance & Operational Excellence

✓ On-time installation and commissioning: All milestones met. SFC/SEE fully functional within 12-day outage.

✓ EMA approval: AVR/PSS models accepted. On-load test validation passed. System now fully compliant with Singapore Grid Code and SOM.

✓ Cyber certification: 3rd-party audit confirmed compliance with Singapore Cybersecurity Act requirements.

✓ Operational reliability: Zero excitation-related trips since commissioning. Start success rate 100%. Voltage control and reactive power performance exceed design specs.

How Bohemia Market & Nidec Build on This Success

The Pulau Seraya reference demonstrates that non-OEM SFC/SEE upgrades can succeed in demanding Siemens + EMA + cyber environments.

The modular Nidec-based approach extends this playbook: faster installation (10–12 days), independent SFC/SEE module replacement, easy to install containerized solutions, and direct integration with your T3000 or third-party DCS.

Plus, Bohemia Market's ICS Secure Data Transfer platform adds a cybersecurity layer that OEM typically leaves to others – making your solution future-ready for NIS2, NERC CIP, and next-generation CII oversight.

The Pulau Seraya Power Station upgrade is not a theoretical case. It's a working reference you can audit.

Connection with the plant operator, grid authority, and cyber auditor available on request.

Why Choose Bohemia Market + Nidec?

The simple answer is: proven project experience combined with best-in-class power electronics and dedicated cybersecurity expertise.

Proven Reference

YTL Power Seraya demonstrates our ability to execute complex SFC/SEE retrofits in demanding Siemens + EMA + cyber environments with zero compromises on compliance or outage control.

Nidec Power Electronics

Global leader in high-power LCI static starters and excitation systems. Containerized, modular MV solutions proven in Italian CCGT revamps and medium-voltage industrial deployments worldwide.

ICS Secure Data Transfer

Industry-leading cybersecurity platform for OT. Hardened OS, MFA, logging, SIEM export, and shared-session remote support – aligned with NERC CIP, NIS2, and CII mandates.

Grid-Code Expertise

Full turnkey compliance: AVRPSS2B/PSS3B models in PSSE/PSCAD format, on-load testing coordination with TSOs (EMA, ENTSOE, NERC), and documentation for regulators.

Fast Deployment

10–12 day outage windows with modular containers, multishift coordination, cable reuse, and zero disruption to adjacent plant systems.

DCS Agnostic

Seamless integration with Siemens T3000/PCS7, Emerson Ovation, or any third-party DCS via Profibus DP, Modbus TCP, Profinet, or IEC 61850.

The ICS SFC/SEE Replacement Service

End-to-end support from assessment through commissioning and long-term warranty.

1. Needs Risk Assessment

Detailed site survey, SFC/SEE condition analysis, grid-code gap mapping, cyber posture review against regional standards.

2. Technical Solution Design

Nidec modular containers, control interfaces, redundancy architecture, IECEN compliance, DCS integration specs.

3. Factory Mock-Up Testing

Full communication and control validation against plant-identical T3000/DCS environment at Nidec factory test center.

4. Compliance Engineering

AVR PSS model development, PSSE/PSCAD export, on-load testing coordination, TSO/EMA/NERC documentation, cyber hardening per IEC 62443.

5. Project Execution

10–12 day installation, multishift coordination with plant and grid operator, cable reuse optimization, minimal civil work.

6. Training (optional)

...

7. Commissioning & Warranty

On-site model validation, TSO validation, handover training, 2-year extended warranty, long-term LTSA support available.

For more information, please contact us

Every company is different, and the state of Industrial Control Systems (ICS) SFC/SEE varies from company to company.

Ageing static frequency converters and excitation systems are causing turbine starts to stop, violating grid codes, and exposing your plant to massive cyber and regulatory risks.

Left unaddressed, this doesn't just mean downtime – it triggers cascading operational, regulatory, and financial exposures.

So, at some point, your SFC/SEE unit will need to be replaced.

Your challenge is to have it replaced with minimal effort, and minimum downtime, while ensuring compliance with the required standards.

We therefore would like to offer you a no-obligations chat about how the ICS SFC/SEE Replacement service can help you keep your plant running with minimal downtime.

Click the button below, fill out the form, and send it to us, and we'll get back to you shortly.